This guide provides instructions on how to correct the correct quantity of a product in stock management in different situations, such as retrospective inventory or changes in the current stock balance. The guide includes step-by-step instructions on inventory mass operations, inventory by shelf location, and utilizing the stock inventory list. Netvisor has a 2-hour timeout, so if large quantities are inventoried, it is recommended to do this in several batches. If the view has not been saved for two hours, the program will terminate the use in the background. The time period can be extended by doing things on another tab, such as retrieving a view, to prevent the timeout.

The inventory entry in stock management can be used to correct the correct quantity of a product in stock management.

- Retrospective inventory

- Change/reset of current stock balance

- Inventory mass operations

- Inventory by shelf location

- Stock inventory list report

Retrospective inventory

The inventory entry view by default records the entry for the day the inventory is made. It can be changed from the inventory date field, so the inventory entry occurs on the specified day.

Set the correct quantity to appear for the correct stock. If the value is also incorrect, it is recommended to first inventory the product to zero on the desired day, check that it no longer has a value, and then make a new inventory entry with the correct value and quantity for the product. When the quantities are correct per stock, press the save changes button. This takes you to the stock report, where the change made for the respective products is visible. The delivery date field will have the day given as the inventory date.

If you want to inventory stock retrospectively, it is advisable to first retrieve, for example, stock reports > inventory report and stock inventory list. Use the extended search and search for the stock situation up to the desired day. Below is an example of searching for the situation until the end of 2023. The start date is left blank.

Check from the report how many products were in stock at the end of the year. If the inventory was made until the end of the year, the report can be printed and manually mark the inventoried quantity for those products, the correct inventoried quantity that was in stock.

If the retrospective inventory entry is made manually with a manual stock entry, proceed as follows

Then make an inventory entry for these products in stock. Now you need to calculate the difference between the current stock quantity and the end-of-year quantity.

Make a stock entry manually with a new stock transaction inventory (Create new > Stock transaction > Inventory). Set the delivery date to the desired day, e.g., the last day of the year.

If there were, for example, -5 in stock at the end of the year and the value is to be reset. Make an inventory entry for the value of 5 and the correct stock and set the purchase price correctly and the delivery date to 31.12.2023. This way, the stock was reset to zero at the end of the year, but the current stock quantity may differ from zero if the product has been purchased or sold after the end of the year.

The delivery date of the inventory can be changed at the point when the stock row is formed. Then edit the delivery date to the desired one.

Change/reset of current stock balance

Before making the inventory, ensure that the product has the correct purchase price.

The inventory entry can be made through the product listing process basket. Search for the desired product/products from the product listing and check them. At the bottom of the screen, select "add selected to process basket". Inventory cannot be made for a product that is not stockable.

Press the downward triangle next to the process basket and select: Perform inventory for products

The view that opens shows the stocks created in Netvisor and how much of the product is in the respective stock. From this view, the quantity of the product can be corrected per stock.

If you do not want to handle all existing stocks, you can select the button "Select stocks to be handled" to bring those stocks visible for inventory entry.

Printable format -button creates a field ________ after the product quantity per stock row, which can be printed by pressing the printer icon in Netvisor. This way, a printable form can be provided to the warehouse staff, where they can manually correct the correct quantity of products. Then the inventory entry can be made based on this when the correct quantity per stock is known.

Below is an image by stock, showing how many pieces of products are in each stock. The summary section calculates the products together. The stock field is the total quantity of products in different stocks, reserved is the quantity of products ordered that have not yet been invoiced. Ordered is the quantity of the product ordered with purchase orders. Purchase price is the purchase price of the product on the product card. Average price is the average price of the stock for the product.

In inventory, you can update the unit price of the desired product (if it is different from the product's average price) and mark it as the product's purchase price. If desired, the average price can also be reset if you want to reset the stock balance and values of the desired product.

Additionally, the "inventory" function can update the number of free links of purchases preceding the inventory to the current level if necessary. (If the company has a batch-based stock valuation method in use).

Below is an example of the initial situation. The product "Test product 1" has 37 pcs without stock and 20 pcs in the stock named "Unit 1".

If the correct situation is that there should be no product without stock and there should actually be 50 pcs of the product in the stock "Unit 1", make the change as shown in the image below. At the same time, change the unit price of the product to 1.5 euros and set it as the product's purchase price:

Then press the save changes button.

This automatically creates stock entries for the products. The type is inventory (unless the stock transaction type has been changed) and the status is handled. The delivery date will be the day the inventory is made. The Specification field will show what the original quantity of the product was and why this changed during the Inventory entry.

Two stock rows were created because it was a change in the balances of two different stocks.

Inventory mass operations

Products can also be updated in bulk to the desired stock. Below is an example of a situation where you want 10 products for all products "not default stock" and 30 products for the stock "unit 1". Enter this information in the top row.

Press the green downward arrow at the end of the row. This updates the changes to all product rows. The red square below this would remove the product row from the process basket.

When changes are made in bulk, they are updated to each product row in the process basket. This also creates stock entries in the background.

Inventory by shelf location

The process basket does not show the shelf location for products, but if a product is inventoried that has a default stock and shelf location defined, the program will inventory the new quantity directly to the specified shelf location and reset any old shelf location for the respective stock.

If a default shelf location is not defined for the product, but it is still desired for the new inventoried row, then the desired shelf location must be manually corrected in the stock row formed after the inventory.

If the product is on multiple shelf locations and these should be corrected to the default shelf location in the future

In this example, the products do not have batch processing enabled.

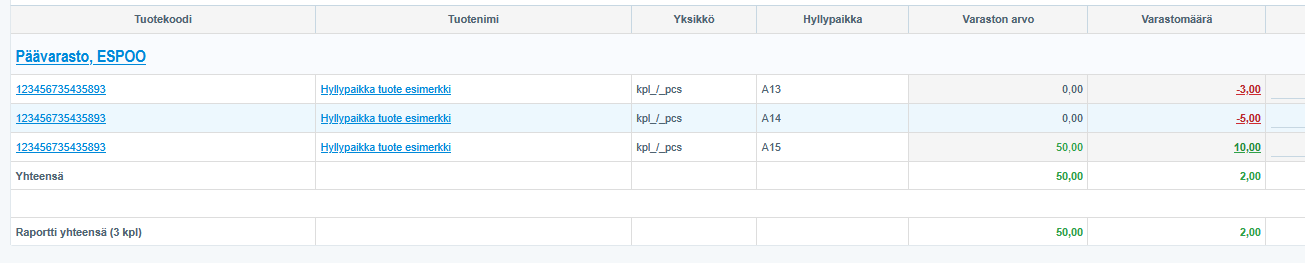

A couple of shelf locations are negative, and ultimately there are 2 products in stock. The default shelf location for the product is A15

Direct inventory does not correct this, as it only updates the default shelf location.

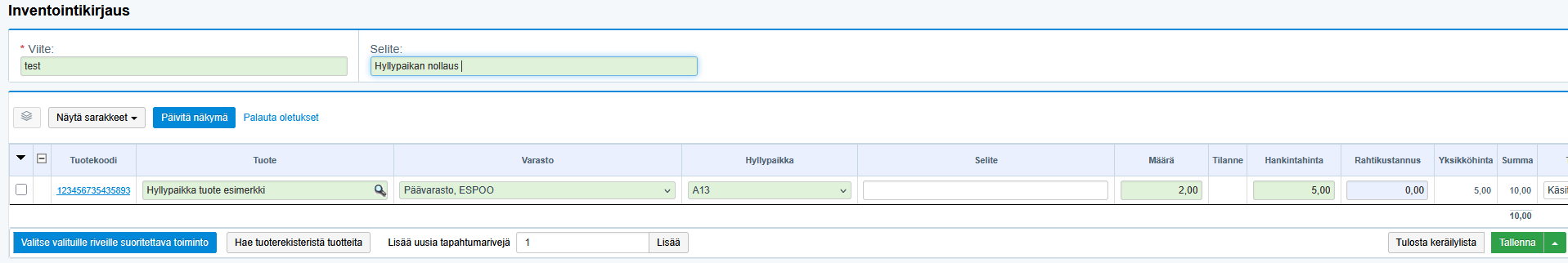

But make a manual entry for the quantity +3 on shelf location A13 and +5 on shelf location A14

Example below, select inventory as the manual stock transaction. In the entry, the shelf location must be manually changed to the desired one.

Same for shelf location A14

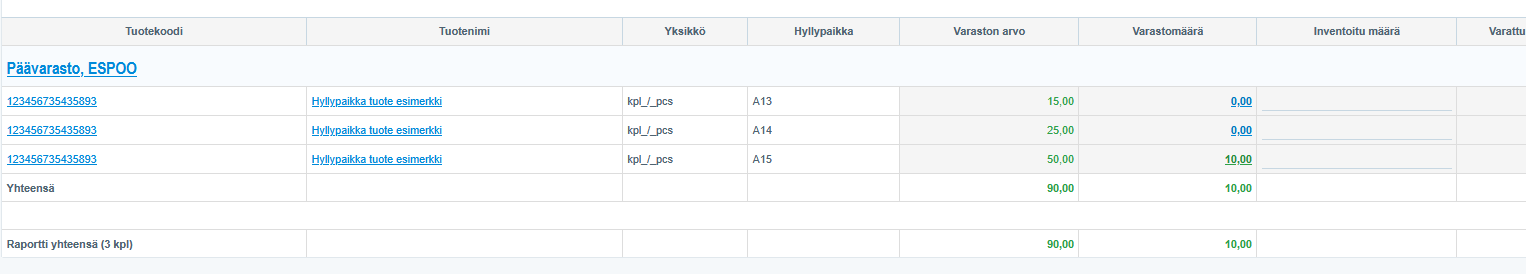

Then the situation is like this, now the old shelf locations are at zero, but the total stock quantity has increased.

If now the default shelf location also needs to be corrected, it can be done in the same way or use inventory through the product list via the process basket and correct the desired quantity there. It updates the default shelf location information at the same time.

Stock inventory list report

The stock reports include a stock inventory list that can be used as an aid before making an inventory entry. The report shows the stock quantity of products per selected stock. If this report is printed, for example, for the warehouse manager, they can go through the products and record the correct quantity of products in the Inventoried quantity field. Then the inventory entry can be made based on this information. The stock reports have instructions on their own help page.

Keywords: Retrospective inventory, inventory entry, stock management, process basket, stock inventory list, shelf locations

Did you find it helpful? Yes No

Send feedback